Discover the T7003 RPT Series: Airclos Leads the Future of Retractable Roofs.

T7003 RPT Uw = 1,4 W/m²K

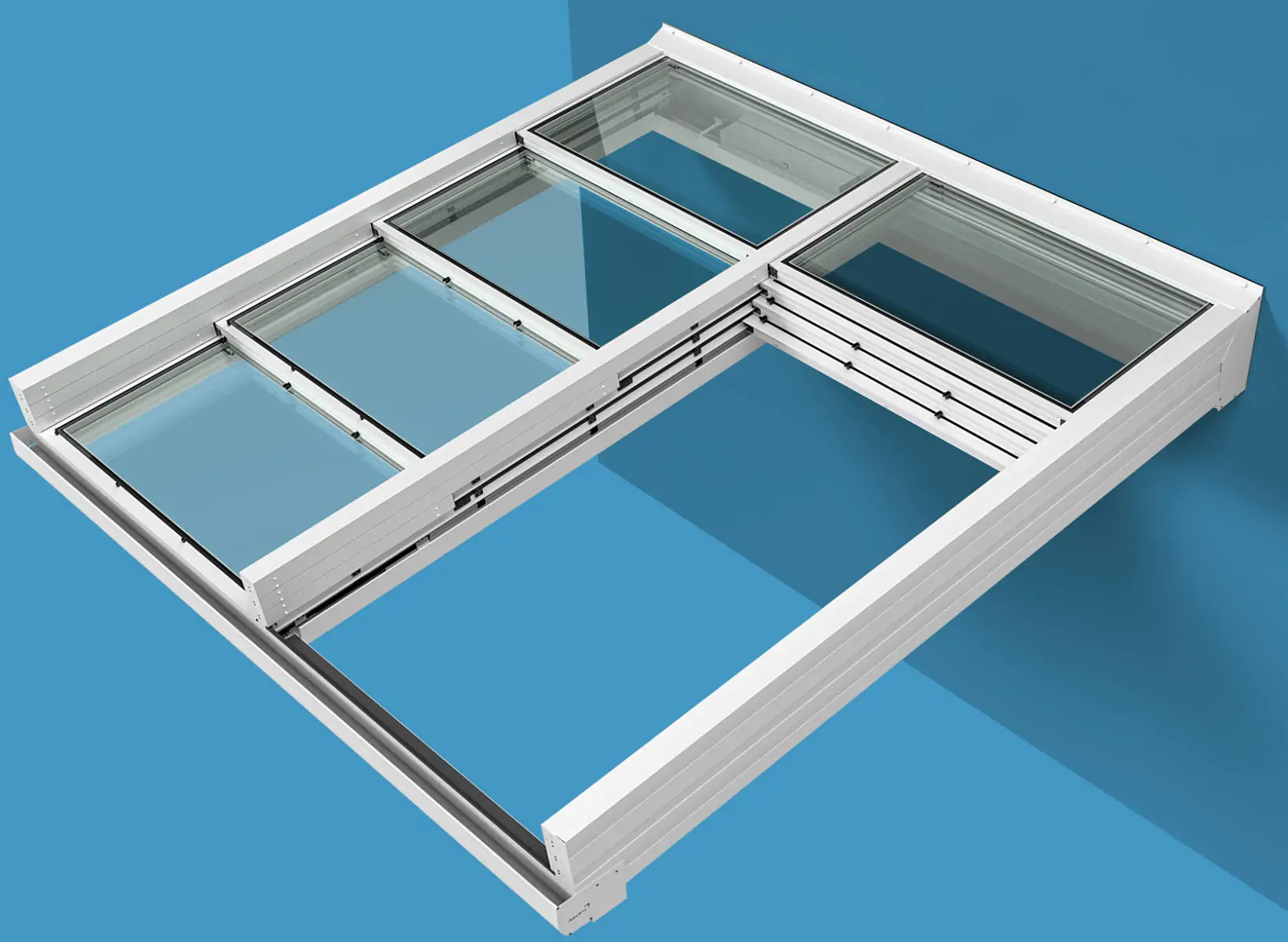

In the constant pursuit of excellence and innovation, Airclos is proud to present the most acclaimed evolution of our series of retractable roofs: the T7003 RPT Series.

Both this series and its predecessor, the T7000 RPT, are unique in the market for featuring thermal break at all contact points, including the guides. This characteristic ensures superior thermal insulation throughout the system with a Uw Value = 1.4 W/m²K, offering unmatched efficiency and comfort.

However, the new T7003 RPT model goes a step further and not only maintains the robustness and modern design of its predecessor but also introduces significant improvements in two crucial aspects for contemporary architecture: sealing and insulation.

Aware of the challenges posed by extreme climates and the need for more efficient and comfortable spaces, we have invested many hours in research and development to exceed our customers' expectations. The T7003 RPT Series is the result of this commitment to innovation and stands as a true pioneer in the enclosure systems industry.

Redefining Excellence:

Key Innovations in the T7003 RPT

Next, we will explore each of these improvements in more detail:

Solutions inherited from the T7000 RPT:

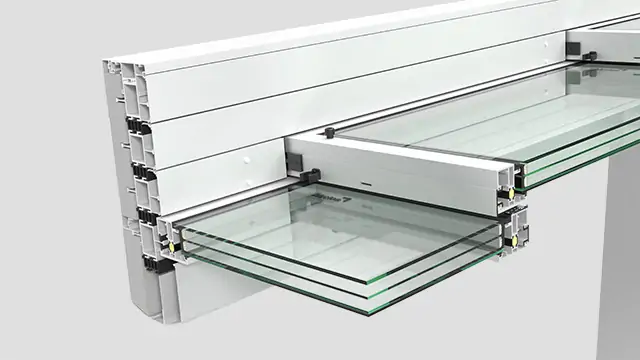

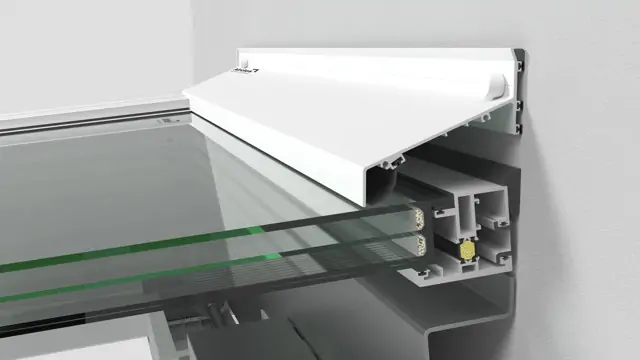

- Triple-glazed panels with RPT: Triple-glazed panels with RPT both on the interior and at the points of contact (Ug value of 0.5 W/m²K).

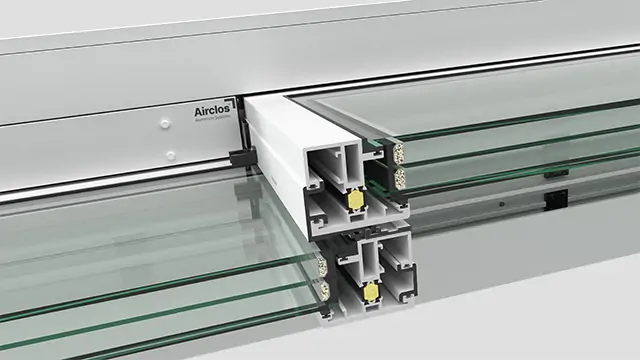

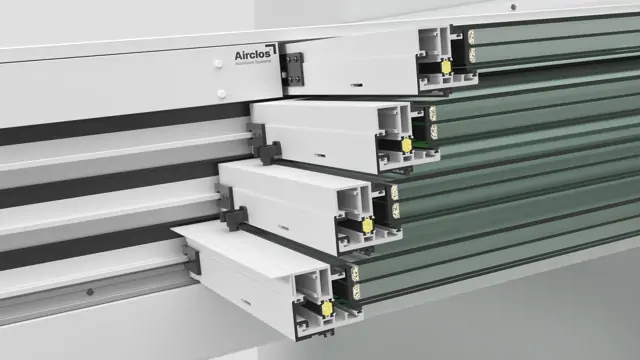

- Central guides with RPT: Polyamide profiles between the guides to avoid contact between them.

- Track covers: Track covers on the guides for greater tightness and seal.

- Etched glass: Glazing system that creates a completely flat surface that prevents water accumulation and improves its drainage.

- Optimized sliding system: Self-lubricating nylon skids for optimal sliding, a hooking drag system, and anti-derailment piece for total security.

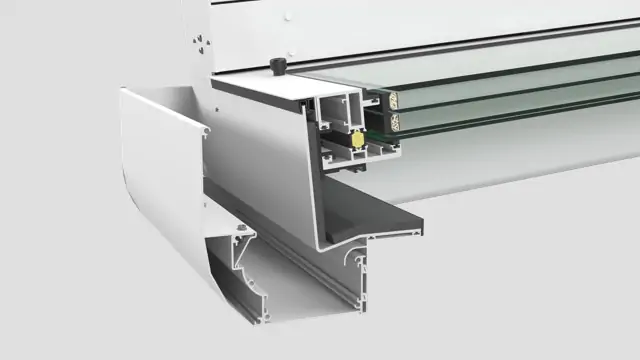

- Rear water drip: The rear includes a water drip to ensure tightness and seal.

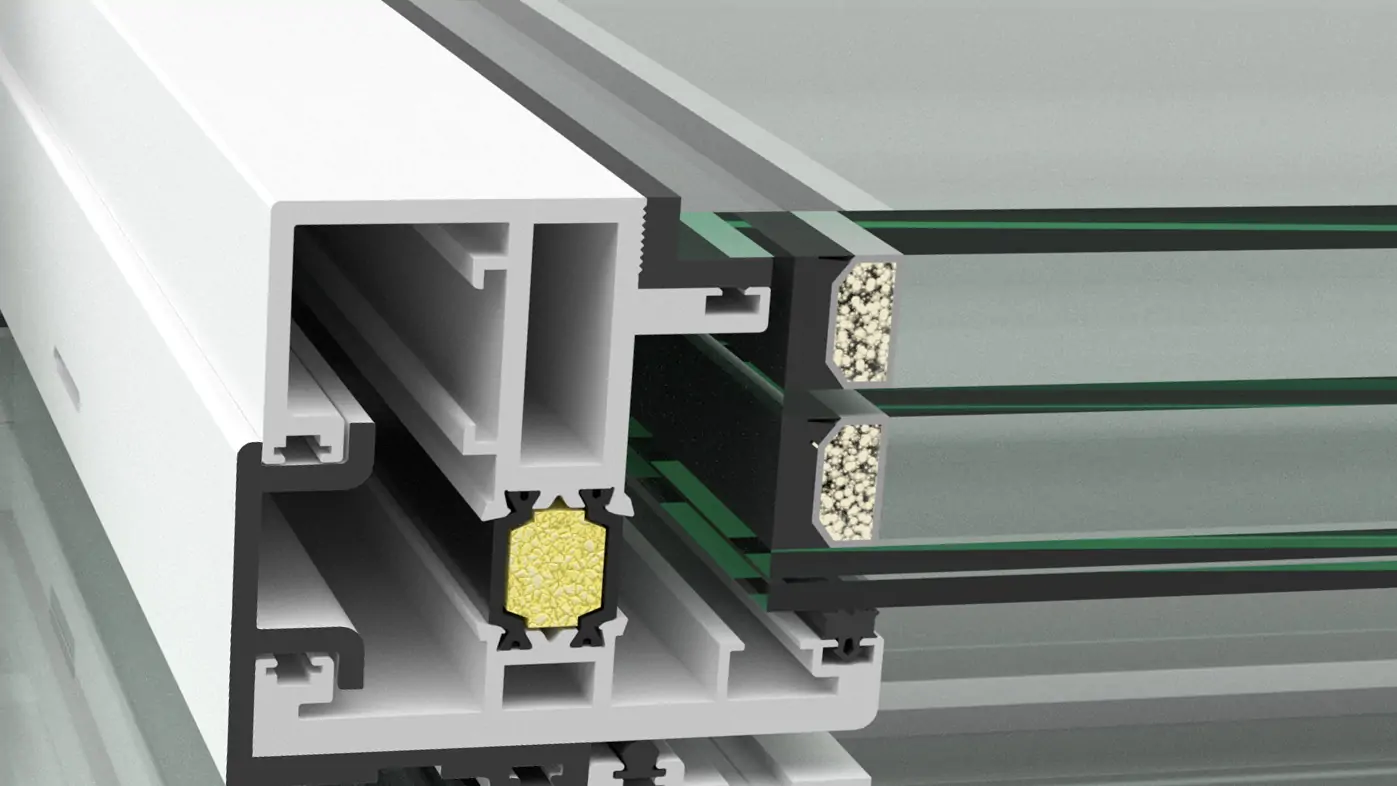

- Polyamide profile between panels: Introduced at the crossing between panels, significantly improving the thermal bridge break. Secured with 3M tape to eliminate any gap between the crossing and the panel.

- Lateral guides: Filled with expanded polystyrene in the lateral guides.

- Optimized rear: Direct contact of the fixed panel with the wall to ensure the RPT.

Innovations introduced in the T7003 RPT:

- Foam seal on the front: Added to optimize tightness and insulation with the motorized panel and the front load carrier.

- Front block under the guides: Designed to cover any gap between the guide and the load carrier, preventing leaks.

- Guide joints: Updated material to maintain the thermal bridge break at the junction points.

- Seal tape on the lateral guides: Applied both at the guide finish and the lateral covers to improve tightness.

- Windbreaker in the guides: Developed to prevent leaks at the point where the panels cross.

- Accessories with more durable finishes: The accessories of the transmission system are now available in INOX or with a cataphoresis finish, significantly increasing their durability.

The Thermal Break in the T7003 RPT

The T7000 RPT was a pioneer with its effective Thermal Break. The T7003 RPT improves this technology, achieving a U-value of 1.4 W/m²K through a longitudinal Thermal Break that covers all contact points between the interior and exterior profiles.

How do we achieve a U-value of 1.4w/m²C in the T7003 RPT?

To achieve this, a longitudinal Thermal Break is created that covers all contact points between the interior and exterior profiles.

As we have seen previously, these key points for the Thermal Break are:

- Inside the leaves.

- Crossing of the leaves.

- Central guides.

- Side guides.

- Front.

- Rear.

Ideal Applications for Retractable Roofs with Thermal Break

This system will be ideal when we need to:

- Reduce energy consumption and environmental impact.

- Attenuate acoustic impact.

Pubs, restaurants, hotels, and other businesses of this kind make a significant investment to ensure the comfort of their customers (in heating, air conditioning, smoke outlets…) and seeking solutions that reduce this cost will be highly profitable.

Additionally, reducing noise for the comfort of the environment is also key in these types of businesses. Therefore, our T7003 RPT series retractable roof is particularly interesting in these cases.

We must consider what happens on the walls. It makes no sense to install a thermal break retractable roof with glass curtains as all the insulation provided by one system is lost in the other. If it is not an interior courtyard or space surrounded by walls, the best combination would be Airclos folding doors with Thermal Break such as the S220 RPT Series and S200 RPT Series.

Other Interesting Details:

What is Thermal Break or RPT?

Thermal Break reduces the transmission of temperature between the exterior and interior of a building by inserting a non-conductive material between the aluminum faces to prevent direct contact and thus temperature transfer. The Thermal Break will be especially beneficial for:

- Energy savings: Reduces air conditioning consumption, increasing energy efficiency and decreasing CO2 emissions.

- Condensation reduction: Prevents condensation on interior profiles in cold climates (which occurs when the outside temperature is very low and there is relative humidity inside).

Triple glass in Airclos retractable roofs

As is customary in our high thermal performance series, the T7003 RPT is manufactured with triple glass, achieving a Ug value of 0.5w/m²C.

The Ug value measures the temperature exchange between the interior and exterior of a room through the glass. The lower the Ug value, the less transmission there is and therefore less heat or cold loss will occur in the home, increasing comfort and reducing energy consumption and environmental impact.

Given that most of the surface of retractable roofs is glass, this represents a considerable improvement in the thermal performance of the entire roof.

How does polyamide affect thermal insulation?

Traditionally, the Thermal Break in aluminum profiles is achieved by inserting insulating polyamide rods, reinforced with 25% fiberglass. This material has a conductivity almost 800 times lower than aluminum, creating a continuous insulating barrier that prevents heat transmission.

How does Polyurethane Foam affect acoustic insulation?

Polyurethane Foam is a synthetic and thermosetting material, highly cross-linked and non-fusible, characterized by offering great resistance to thermal and acoustic transmission.

It has a high insulating capacity due to the low thermal conductivity of the foaming gas in its closed cells. This represents a 25% improvement compared to the average of other products used in thermal insulation.

Distribute our systems with exclusive advantages